Gratings are to be fabricated to required sizes without damaging its structural stability. The cut parts need to be cured with resin to keep its anti-corrosion property.

1. Cutting

Arc cutting machine, angle grinder, electric drill

Safety protection:

The operators should wear protective glasses and masks to prevent from fragments splashing or dust inhalation; wear gloves and overalls to prevent from potential skin allergy; check tools to make sure it safe to use; do cutting at a place where it’s bright and ventilative.

Cutting tolerance:

Cutting tolerance is usually ±5mm due to blade thickness or cutting in or along loading bars.

Curing:

The cut parts need to be cured with correct resin to keep its surface integrity.

2. Fabrication Plan

1) Before production, the grating area need to be counted in outer dimension and take cutting loss into consideration.

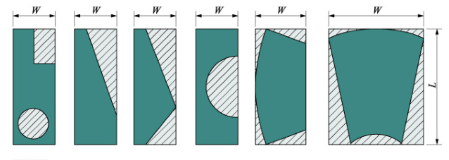

2) For special shapes (as shown below), the area is counted in length by width. The cut-off part should be count in.

3. Installation

FRP gratings are to be installed according to engineering design, which can be concluded to 4 types: trench installation; platform (structural) installation; staircase installation; flooring installation

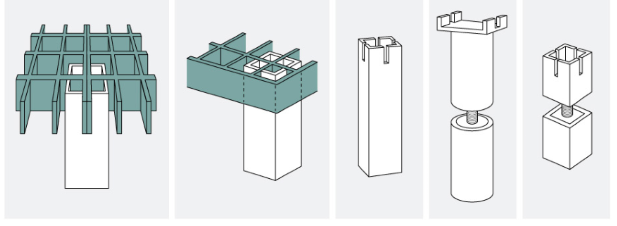

a.Trench Installation

The installation slot depth should be 1mm to 2mm deeper than grating height and width should be no less than 38mm. The gap between grating and trench edge should be 3mm to 6mm. If the user requires the gratings with all edges closed, we recommend the contractors calculate or consult us the closed-cell size of gratings and build the trench to match the closed-cell grating size. We can supply “Y”shape beam, which can be embedded in concrete and be used as frame for trench cover.

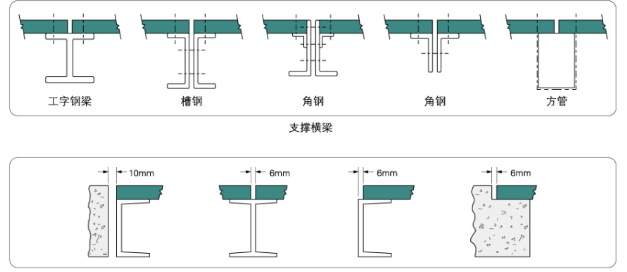

b.Platform (structural) Installation

The support tape under grating should be at least 40mm wide. There should leave 10mm space between grating and underside structure, for installation handling. The joining position of two gratings needs to be supported for stability consideration. At least 4 sets of fasteners recommended for each panel, fixed by bolts and nuts. If the support structure’s not anti-corrosive, we recommend to do anti-corrosive coating.

c.staircase installation

Grating steps should be installed within the frame; The two ends of steps can be fixed to frame by using FRP angles as connectors. At least 1 set of fastener recommended for each end of a step. A highlighted colour nosing recommended for easy recoganizing.

d.Flooring Installation

Gratings are to be fixed tightly in case of moving.

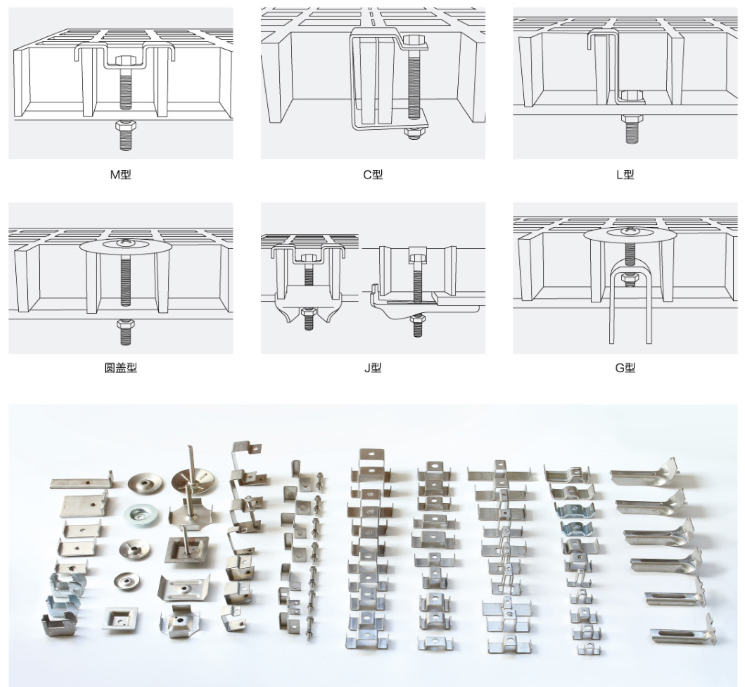

4.Fasteners

5.Maintainence

When the gratings got dirty, please clean with water flushing. Neutral detergent can be used if it necessary; Please avoid high temperature, direct contact of flame or stiff/sharp tools scratch or impact. Please replace the gratings if it structurally damaged or corroded.