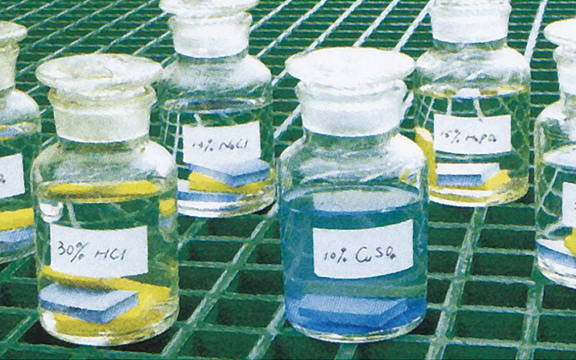

Corrosion Resistance

Mincom molded FRP gratings has the superiority in the field of anti corrosion. It can resist effectively corrosion of acid and alkali, organic solvents and salts, either gas or liquid. Different from traditional metal gratings, it will not go rusty when contacted by chemicals because no electrochemical action would happen, which keep the grating away from any structure damage. And compared to other materials like wood, it’s free of any rot or mildew. So no maintenance is required. It is an ideal substitute for metal, wood or concrete. We have in our system resins of orthophthalic, isophthalic, vinylester and phenolic to meet requirements of different application.

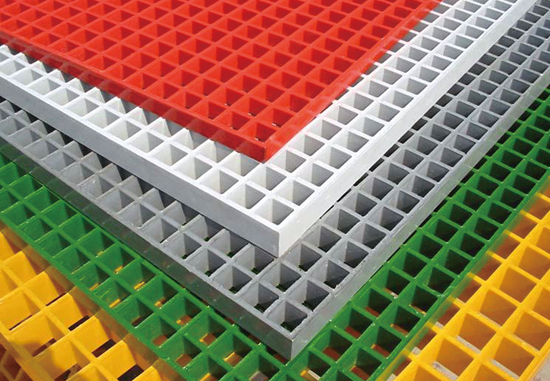

High strength-to-weight ratio

FRP molded grating is low density composite of resin and fiberglass. Its density is only 1/4 of steel, 2/3 of aluminum. But its strength is 10 times higher than the hard PVC. The absolute strength is higher than aluminum, almost strong as ordinary steel. Its light weight allows less base support, reducing material costs. The light weight feature also makes installation work easy and reduces installation cost.

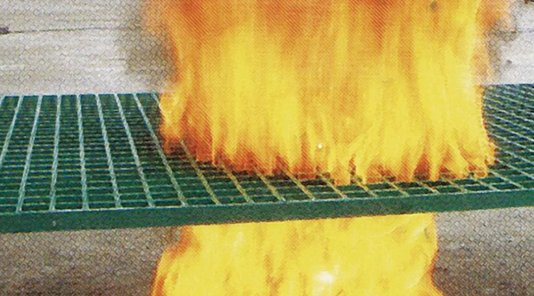

Fire Retardanct

The oxygen index of the ordinary FRP molded grating (according to GB 8924 test) is over 32. As per customer’s request, we can supply gratings with class 1 (ASTM E-84 test) flame spread index; High fire retardant vinylester grating has a better property with flame spread index less than 10 and is certified by ABS. Mincom's specially designed formula can meet the requirements of the fire safety to ensure safety.

Impact resistance and fatigue resistance

FRP grating has a high impact strength, allowing repeated bending with no permanent deformation. Its moderate elasticity makes employees feel comfortable when they stand on the gratings for long time. It’s the best solution to ease strain on the backs, legs or feet, which is beneficial to improve production efficiency.

Anti-slip

FRP molded grating is anti-slip, either with natural concave surface or gritted surface. The gritted surface can be made in two craftworks: in-mould gritted and bonding after finish. Both two type provides excellent anti-slip function. The grits are stable and durable. As per authoritative reports, slipping accidents accounts for second of the personnel safety incidents. In many factories slipping has become the main cause of the accidents and caused huge economic losses. The use of FRP brings not only safety but also comfort. It decreases enormously the risk of slipping accidents.